ACS Solidifies Global Role As Professional Wear Resistance Surface Protection Film Manufacturer With ROHS Certification

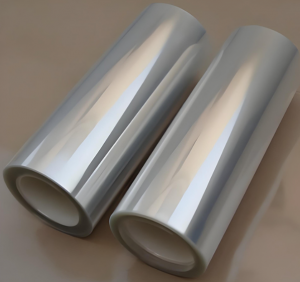

FOSHAN, GUANGDONG, CHINA, January 12, 2026 /EINPresswire.com/ -- Foshan AoChuanShun New Material Industrial Co., Ltd. (commonly referred to as ACS) has formally announced the alignment of its functional film production standards with international environmental and durability benchmarks. As a Professional Wear Resistance Surface Protection Film Manufacturer, ACS specializes in the development of specialized polyethylene terephthalate (PET) and multi-layer composite films engineered to endure high-friction industrial environments. These wear-resistant products are designed with a specific surface hardness that prevents scratches, abrasions, and scuffs on sensitive substrates such as high-gloss plastics, treated metals, and optical glass. By utilizing advanced cross-linking coating technology, the manufacturer provides a protective barrier that maintains surface integrity during complex manufacturing assembly, high-speed automated handling, and long-distance maritime logistics.

I. Industry Outlook: Emerging Trends in Surface Protection Technology

The global market for functional films is currently undergoing a technical transition driven by the advancement of precision manufacturing in the electronics, automotive, and appliance sectors. As product surfaces become more sophisticated—incorporating touch sensors, matte finishes, and high-transparency layers—the requirement for protective materials has shifted from simple dust covers to high-performance functional films.

1. Technological Evolution of Material Resilience

Mechanical Durability in Automation: In modern automated factories, components are often subjected to robotic gripping and high-velocity friction during the assembly line process. Consequently, the industry is prioritizing films with enhanced wear resistance that do not compromise optical clarity or interfere with high-resolution sensors.

Adaptation to Complex Form Factors: The rise of flexible and foldable electronic devices has further necessitated the development of films with specific elongation and fatigue-resistance properties. These materials must protect surfaces while undergoing repetitive mechanical movement without delaminating or losing their protective properties.

Heat and Chemical Stability: Beyond physical wear, industry trends show an increasing need for films that remain stable under thermal stress and chemical exposure, particularly during the cleaning or curing phases of high-tech manufacturing.

2. Market Dynamics and Consumer Expectations

Aesthetic Preservation: For premium brands, the "unboxing" experience is paramount. Even microscopic abrasions during shipping can lead to product returns. This has pushed manufacturers to adopt specialized wear-resistant layers that preserve the factory-fresh appearance of high-gloss surfaces.

Miniaturization Demands: As devices become thinner, the tolerance for protective material thickness decreases. The industry is moving toward "thinner but stronger" film profiles that offer equivalent protection levels with reduced plastic bulk.

II. The Strategic Importance of RoHS Certification in Global Trade

The attainment and maintenance of RoHS (Restriction of Hazardous Substances) certification represents a critical milestone in the professionalization of the film manufacturing sector. This directive, originating from the European Union but adopted as a global benchmark, restricts the use of specific hazardous substances.

1. Chemical Safety and Regulatory Compliance

Substance Restriction: RoHS ensures that ACS films are free from hazardous materials such as lead, mercury, cadmium, and specific flame retardants. This is vital because protective films are in prolonged contact with consumer-facing surfaces.

Foundational Quality Infrastructure: For ACS, RoHS compliance is not merely a regulatory checkbox but a foundational element of its production framework. It ensures that the chemical composition of both the PET substrate and the adhesive coating remains non-toxic and environmentally safe.

Verification Protocols: Compliance requires rigorous testing of raw materials. This systematic approach to chemical monitoring enhances the overall reliability of the manufacturing process, reducing the risk of batch-to-batch variation.

2. Facilitating International Market Access

Global Trade Passport: RoHS certification provides international procurement officers with the assurance that materials will not trigger compliance failures at customs or during final product testing in regulated markets.

Risk Mitigation for Brands: Multinational corporations often face severe legal and reputational risks if their supply chain contains restricted substances. By providing certified RoHS-compliant films, ACS mitigates these risks for its global partners.

Environmental Responsibility: Beyond legal compliance, adhering to these standards reflects a commitment to the circular economy. Non-hazardous materials are significantly easier to manage during the waste disposal and recycling phases of the product lifecycle.

III. ACS: Core Competencies and Technical Applications

Foshan AoChuanShun New Material Industrial Co., Ltd. has established its market presence through a focus on technical precision and customized material engineering, addressing the intersection of physical durability and adhesive science.

1. Manufacturing Excellence and Quality Infrastructure

Cleanroom Production Environments: To serve the optical and semiconductor markets, ACS operates advanced coating lines within strictly controlled dust-free environments. This is essential for wear-resistant films, as any particulate contamination during the coating process could result in surface defects on the protected product.

Stable Peel Strength Engineering: The technical team focuses on modulating adhesive cross-linking density. This ensures that the films adhere firmly during processing and shipping but can be removed cleanly without leaving ghosting residues, even after exposure to heat.

Standardized Quality Management: Utilizing ISO 9001 frameworks, the company maintains a rigorous inspection regime that monitors tensile strength, surface hardness, and adhesive thickness across every production run.

2. Primary Application Scenarios and Industrial Use

Consumer Electronics: Protecting touchscreens, camera lenses, and mobile phone casings during CNC machining and high-speed assembly where abrasion resistance is a primary requirement.

Automotive Surface Protection: Safeguarding high-gloss dashboards, center consoles, and decorative trims from micro-scratches during vehicle assembly and long-distance logistics.

Optical Materials Industry: Serving as a temporary carrier or protective layer for polarizers, diffusers, and brightness enhancement films (BEF) within display modules, where maintaining high transparency is paramount.

Precision Industrial Parts: Providing wear-resistant barriers for stainless steel panels and glass components used in high-end appliances, preventing damage during the stacking and handling phases.

Conclusion

As the global manufacturing landscape continues to demand higher levels of precision and environmental accountability, the role of specialized material suppliers becomes increasingly vital. Foshan AoChuanShun New Material Industrial Co., Ltd. (ACS) remains committed to advancing the technical capabilities of surface protection films while adhering to the rigorous safety standards set by RoHS certification. Through the integration of wear-resistant technology and sustainable chemical practices, ACS provides the industrial sector with reliable tools to protect product value and ensure manufacturing excellence on a global scale. The combination of mechanical strength and international compliance ensures that every surface protected by ACS remains in its intended pristine condition from the factory floor to the end consumer.

For additional information regarding product technical data, environmental certifications, or custom material inquiries, please visit the official corporate website: https://www.acs-plasfilm.com/

I. Industry Outlook: Emerging Trends in Surface Protection Technology

The global market for functional films is currently undergoing a technical transition driven by the advancement of precision manufacturing in the electronics, automotive, and appliance sectors. As product surfaces become more sophisticated—incorporating touch sensors, matte finishes, and high-transparency layers—the requirement for protective materials has shifted from simple dust covers to high-performance functional films.

1. Technological Evolution of Material Resilience

Mechanical Durability in Automation: In modern automated factories, components are often subjected to robotic gripping and high-velocity friction during the assembly line process. Consequently, the industry is prioritizing films with enhanced wear resistance that do not compromise optical clarity or interfere with high-resolution sensors.

Adaptation to Complex Form Factors: The rise of flexible and foldable electronic devices has further necessitated the development of films with specific elongation and fatigue-resistance properties. These materials must protect surfaces while undergoing repetitive mechanical movement without delaminating or losing their protective properties.

Heat and Chemical Stability: Beyond physical wear, industry trends show an increasing need for films that remain stable under thermal stress and chemical exposure, particularly during the cleaning or curing phases of high-tech manufacturing.

2. Market Dynamics and Consumer Expectations

Aesthetic Preservation: For premium brands, the "unboxing" experience is paramount. Even microscopic abrasions during shipping can lead to product returns. This has pushed manufacturers to adopt specialized wear-resistant layers that preserve the factory-fresh appearance of high-gloss surfaces.

Miniaturization Demands: As devices become thinner, the tolerance for protective material thickness decreases. The industry is moving toward "thinner but stronger" film profiles that offer equivalent protection levels with reduced plastic bulk.

II. The Strategic Importance of RoHS Certification in Global Trade

The attainment and maintenance of RoHS (Restriction of Hazardous Substances) certification represents a critical milestone in the professionalization of the film manufacturing sector. This directive, originating from the European Union but adopted as a global benchmark, restricts the use of specific hazardous substances.

1. Chemical Safety and Regulatory Compliance

Substance Restriction: RoHS ensures that ACS films are free from hazardous materials such as lead, mercury, cadmium, and specific flame retardants. This is vital because protective films are in prolonged contact with consumer-facing surfaces.

Foundational Quality Infrastructure: For ACS, RoHS compliance is not merely a regulatory checkbox but a foundational element of its production framework. It ensures that the chemical composition of both the PET substrate and the adhesive coating remains non-toxic and environmentally safe.

Verification Protocols: Compliance requires rigorous testing of raw materials. This systematic approach to chemical monitoring enhances the overall reliability of the manufacturing process, reducing the risk of batch-to-batch variation.

2. Facilitating International Market Access

Global Trade Passport: RoHS certification provides international procurement officers with the assurance that materials will not trigger compliance failures at customs or during final product testing in regulated markets.

Risk Mitigation for Brands: Multinational corporations often face severe legal and reputational risks if their supply chain contains restricted substances. By providing certified RoHS-compliant films, ACS mitigates these risks for its global partners.

Environmental Responsibility: Beyond legal compliance, adhering to these standards reflects a commitment to the circular economy. Non-hazardous materials are significantly easier to manage during the waste disposal and recycling phases of the product lifecycle.

III. ACS: Core Competencies and Technical Applications

Foshan AoChuanShun New Material Industrial Co., Ltd. has established its market presence through a focus on technical precision and customized material engineering, addressing the intersection of physical durability and adhesive science.

1. Manufacturing Excellence and Quality Infrastructure

Cleanroom Production Environments: To serve the optical and semiconductor markets, ACS operates advanced coating lines within strictly controlled dust-free environments. This is essential for wear-resistant films, as any particulate contamination during the coating process could result in surface defects on the protected product.

Stable Peel Strength Engineering: The technical team focuses on modulating adhesive cross-linking density. This ensures that the films adhere firmly during processing and shipping but can be removed cleanly without leaving ghosting residues, even after exposure to heat.

Standardized Quality Management: Utilizing ISO 9001 frameworks, the company maintains a rigorous inspection regime that monitors tensile strength, surface hardness, and adhesive thickness across every production run.

2. Primary Application Scenarios and Industrial Use

Consumer Electronics: Protecting touchscreens, camera lenses, and mobile phone casings during CNC machining and high-speed assembly where abrasion resistance is a primary requirement.

Automotive Surface Protection: Safeguarding high-gloss dashboards, center consoles, and decorative trims from micro-scratches during vehicle assembly and long-distance logistics.

Optical Materials Industry: Serving as a temporary carrier or protective layer for polarizers, diffusers, and brightness enhancement films (BEF) within display modules, where maintaining high transparency is paramount.

Precision Industrial Parts: Providing wear-resistant barriers for stainless steel panels and glass components used in high-end appliances, preventing damage during the stacking and handling phases.

Conclusion

As the global manufacturing landscape continues to demand higher levels of precision and environmental accountability, the role of specialized material suppliers becomes increasingly vital. Foshan AoChuanShun New Material Industrial Co., Ltd. (ACS) remains committed to advancing the technical capabilities of surface protection films while adhering to the rigorous safety standards set by RoHS certification. Through the integration of wear-resistant technology and sustainable chemical practices, ACS provides the industrial sector with reliable tools to protect product value and ensure manufacturing excellence on a global scale. The combination of mechanical strength and international compliance ensures that every surface protected by ACS remains in its intended pristine condition from the factory floor to the end consumer.

For additional information regarding product technical data, environmental certifications, or custom material inquiries, please visit the official corporate website: https://www.acs-plasfilm.com/

Foshan Ao Chuan Shun New Materials Industry Co., Ltd.

Foshan Ao Chuan Shun New Materials Industry Co., Ltd.

+86 18924854433

daphne@aochuanshun.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.